-

XDD was selected because we wanted someone who would listen and understand the issues at the site. Bringing XDD into the project didn’t save short term funds, but it did save 5 years of extra time on the project…

Benne C. Hutson, McGuireWoods LLP

-

One of their biggest advantages is that XDD gets the results they say they will, on schedule, and within budget.

Christopher Gasinski, Tampa Electric

-

I really can’t think of anything that I’d have you do better. Other than get cheap permanganate, but I know that’s not under your control.” – with respect to in situ chemical oxidation design.

Derek Pinkham, Tetra Tech, EC Inc.

- Catalyzed Hydrogen Peroxide (CHP)

- Alkaline Activated Persulfate (AAP)

- Micron Scale Zero Valent Iron (ZVI) and Nickel Catalyzed ZVI

- Nano-scale ZVI

The results of the treatability testing indicated that AAP applied at 50 g/L provided a high certainty of meeting the remedial goals without the persistence of undesirable end products. The AAP reduced CT by > 98% with three applications, at a concentration of 200 g/L only a single application of AAP was required. CHP was also effective, but site-specific concerns associated with the associated gas evolution eliminated this technology from further consideration. The ZVI technologies also effectively treated CT, but persistent daughter products also eliminated this technology from consideration for the pilot testing.

Based on the bench test results, XDD Environmental both completed pilot testing followed by a full-scale AAP application at the site, using a recirculation based injection strategy. Groundwater monitoring results indicated that project objectives were met for both CT and PCE.

The results of the treatability testing indicated that AAP applied at 50 g/L provided a high certainty of meeting the remedial goals without the persistence of undesirable end products. The AAP reduced CT by > 98% with three applications, at a concentration of 200 g/L only a single application of AAP was required. CHP was also effective, but site-specific concerns associated with the associated gas evolution eliminated this technology from further consideration. The ZVI technologies also effectively treated CT, but persistent daughter products also eliminated this technology from consideration for the pilot testing.

Based on the bench test results, XDD Environmental both completed pilot testing followed by a full-scale AAP application at the site, using a recirculation based injection strategy. Groundwater monitoring results indicated that project objectives were met for both CT and PCE.

Please click here for the full presentation of the treatability testing through full-scale application results

XDD Environmental and Bioremediation Consulting, Inc. (acquired by XDD Environmental in 2013) was contracted by Nobis Engineering, Inc. to evaluate the potential for anaerobic in situ bioremediation to treat a recalcitrant PCE hotspot in fractured bedrock at the Eastern Surplus Superfund Site in Meddybemps ME. The ultimate goal being to avoid restarting a previously installed pump and treat containment system at the site. Treatability testing was performed by XDD Environmental to determine:

- Reagent requirements to achieve complete enhanced reductive dechlorination (ERD) of the PCE

- Evaluating the potential for creating metals mobility as a result of the ERD

- Developing remedial design parameters

Result: The microcosm experiment demonstrated:

- Site groundwater required the addition of organic and mineral amendments and inoculation with dechlorinating culture to effective treat the PCE to ethane in a timely and cost-effective manner.

- There was minimal potential for metals mobility and site-specific metals of concern aluminum, arsenic and lead were extensively removed by precipitation, consistent with the literature.

The treaability testing results were used in the design of the pilot / full-scale application at the site by XDD Environmental. The field implementation was successful and lead to the Maine Department of Environmental Protection being able to keep from re-activating the pump and treat containment system.

The treaability testing results were used in the design of the pilot / full-scale application at the site by XDD Environmental. The field implementation was successful and lead to the Maine Department of Environmental Protection being able to keep from re-activating the pump and treat containment system.

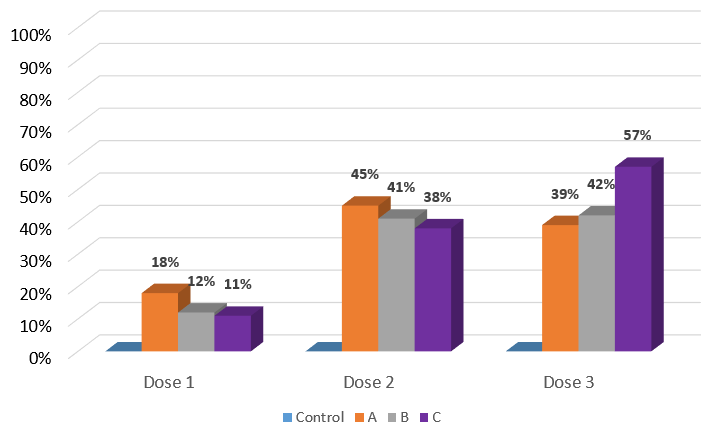

XDD performed treatability testing to confirm reagent dosing requirements that were recommended by several product vendors for a bioremediation project. Comparison of oxygen release products:

Comparison of oxygen release products:

- Treatability testing evaluated several oxygen release compounds (A, B, and C)

- Manufacturer’s recommended dosing was based on achieving complete degradation of target compounds

- Provided manufacturers with site specific data and requested recommended dosing

- Tested all products at maximum recommended dosage

- Select vendors recommended that the dosage estimate be confirmed via testing

- Maximum recommended dose from manufacturers reduced target compounds by only 11% to 18%

- Second and third dosing were still unable to reduce target compounds below project goals

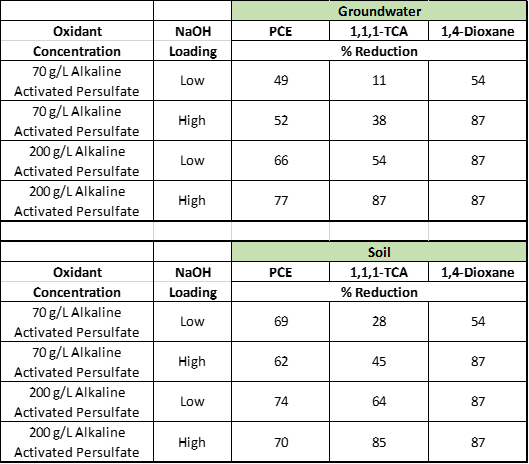

XDD Environmental completed treatability testing of in situ chemical oxidation (ISCO) for contaminants of concern (COCs) measured in soil and groundwater at an active facility located in North Berwick, Maine. The treatability testing assessed oxidant effectiveness for site COCs including tetrachloroethene (PCE), 1,1,1-trichloroethane (1,1,1-TCA), and 1,4-dioxane, all in the milligrams per liter concentration range. The treatability testing results determined that alkaline activated persulfate (AAP) was the most applicable ISCO technology to meet the site-specific goals with high certainty for all the COCs. The results were used in the design of the full-scale field application of ISCO at the site. The field implementation was successful in meeting the client goals for the ISCO at the site in a timely and safe manner.

Bench-Scale Evaluation Approach

The ISCO treatability tests evaluated the ability of a number of ISCO technologies to treat the COCs on site soil and in groundwater. ISCO technologies evaluated included heat-activated persulfate, chelated iron-activated persulfate (to bind up transition metals in the soil matrix to overcome potential interferences with the oxidant), and an industry available packaged ISCO product. CHP and ozone were eliminated from consideration due to client concerns with enhanced vapor migration into the active operating facility that ran 3 shifts of workers directly above the shallow target treatment area. AAP was determined to be the most appropriate technology based on a Phase 1 – Failure Evaluation test. AAP is based on the “activation” of sodium persulfate under alkaline conditions (i.e., pH above pH 10.5). Several concentrations of sodium hydroxide (NaOH) and sodium persulfate were evaluated during the bench tests.

Results

The treatability testing results (shown in the following table) indicated that AAP achieved the greatest reduction in COC concentrations on site soil and in groundwater.

As a result treatability testing, XDD Environmental designed and implemented a pay for performance full scale application of AAP at the site. Annual post-application monitoring confirmed that the client objectives for the ISCO were met and no rebound occurred. COCs concentrations in the treatment area were reduced to low microgram per liter levels for all COCs.