Below are excerpts taken from EPA publication: Guide to Thermal Desorption

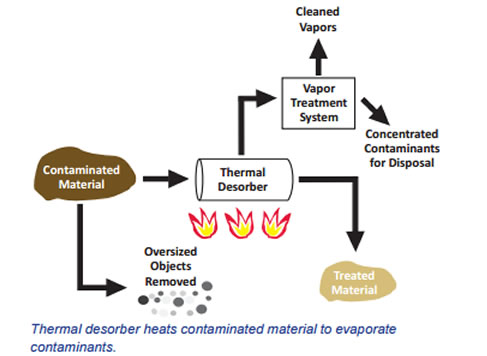

Thermal desorption removes organic contaminants from soil, sludge or sediment by heating them in a machine called a “thermal desorber” to evaporate the contaminants. Evaporation changes the contaminants into vapors (gases) and separates them from the solid material. Many organic contaminants can be removed by thermal desorption. These include volatile organic compounds or “VOCs” and some semi-volatile organic compounds or “SVOCs.” VOCs such as solvents and gasoline evaporate easily when heated. SVOCs require higher temperatures to evaporate and include diesel fuel, creosote (a wood preservative), coal tar, and several pesticides. Thermal desorption generally is not used to treat metals but can partially remove metals like mercury and arsenic, which evaporate at the temperatures sometimes reached in thermal desorption.

How Does It Work?

Thermal desorption involves excavating soil or other contaminated material for treatment in a thermal desorber. The desorber may be assembled at the site for onsite treatment, or the material may be loaded into trucks and transported to an offsite thermal desorption facility. To prepare the soil for treatment, large rocks or debris first must be removed or crushed. The smaller particle size allows heat to more easily and evenly separate contaminants from the solid material. If the material is very wet, the water may need to be removed to improve treatment. This water removed may require treatment using other methods.

The prepared soil is placed in the thermal desorber to be heated. Low-temperature thermal desorption is used to heat the solid material to 200-600ºF to treat VOCs. If SVOCs are present, then high-temperature thermal desorption is used to heat the soil to 600-1000ºF. Gas collection equipment captures the contaminated vapors.

Vapors often require further treatment, such as removing dust particles. The remaining organic vapors are usually destroyed using a thermal oxidizer, which heats the vapors to temperatures high enough to convert them to carbon dioxide and water vapor. At some sites with high concentrations of organic vapors, the vapors may be cooled and condensed to change them back to a liquid form. The liquid chemicals may be recycled for reuse, or treated by incineration. If the concentrations of contaminants are low enough, and dust is not a problem, the vapors may be released without treatment to the atmosphere.

How Long Will It Take?

Thermal desorption may take from a few weeks to a few years. The actual cleanup time will depend on several factors. For example, thermal desorption may take longer where:

• The contaminated area is large or deep.

• Contaminant concentrations are high.

• The soil contains a lot of dust, clay, or organic material, which causes contaminants to stick to the

soil and not evaporate easily.

• A lot of debris must be crushed or removed.

• The capacity of the desorber is small. (Most thermal desorbers can clean over 25 tons of contaminated material per hour.)

Why Use Thermal Desorption?

Thermal desorption is typically used to clean up soil that is contaminated with VOCs and SVOCs at depths shallow enough to reach through excavation. Thermal desorption may be faster and provide better cleanup than other methods, particularly at sites that have high concentrations of contaminants. A faster cleanup may be important if a contaminated site poses a threat to the community or needs to be cleaned up quickly so that it can be reused.